Safety

Safety Blog

Today we will learn about SCBA Set which is used in chemical industry for emergency conditions as well as rescue. This is also known as breathing apparatus Equipment.

Today we will learn about SCBA Set which is used in chemical industry for emergency conditions as well as rescue. This is also known as breathing apparatus Equipment.

- SCBA - SELF CONTAINED BREATHING APPARATUS

- SCUBA - SELF-CONTAINED UNDERWATER BREATHING APPARATUS. (This is used to breath underwater )

Here we will learn ....

- Self contained breathing apparatus parts

- Types of SCBA

- Self contained breathing apparatus details

- Uses of Self- Contained Breathing Apparatus

- Self contained breathing apparatus specifications

- Cylinder carrying Practice

- Check points of breathing apparatus etc.

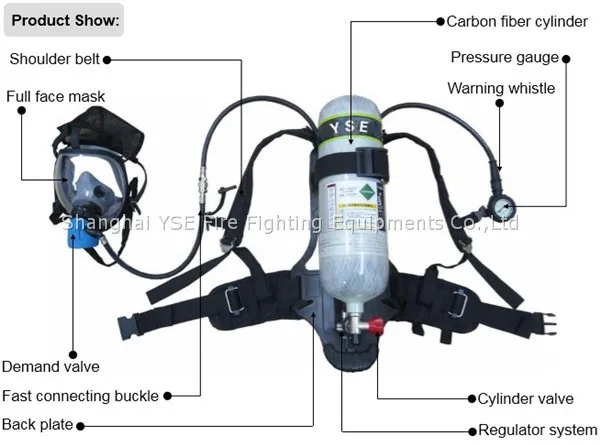

1. Self contained breathing apparatus parts

SCBA Set consists of following parts:

High pressure cylinder - Pressure gauge, Air regulator

Inhalation connection – Face shield, hose, Pressure regulator

Back plate – Waist belt, Shoulder strip, Remote

pressure gauge, Bypass valve, PASS Alarm [Personal alert safety system alarm].

High pressure cylinder - Pressure gauge, Air regulator

Inhalation connection – Face shield, hose, Pressure regulator

Back plate – Waist belt, Shoulder strip, Remote

pressure gauge, Bypass valve, PASS Alarm [Personal alert safety system alarm].

Construction material of SCBA set

Air pressure cylinder is the most important and critical part of SCBA Set.

Cylinder is made with :

2. Types of SCBA

There are two primary types of SCBA

Q. WHAT SIZE CYLINDER DO I NEED?

Q. WHAT KIND OF APPLICATIONS NEED SCBA?

EXAMPLES INCLUDE:

Working with liquids, gases, vapors and particulate

• HAZMAT response to toxic gas leaks such as chlorine and hydrogen sulfide.

Q. WHAT IS A CONFINED SPACE?

Q. WHAT IS A PERMITTED CONFINED SPACE?

Q. WHAT IS A HAZARDOUS ATMOSPHERE IN A CONFINED SPACE?

Q. WHAT KIND OF SCBA MIGHT BE NEEDED?

Q. HOW DOES AN ATMOSPHERE BECOME OXYGEN DEFICIENT?

Q. WHAT DOES OSHA REQUIRE WHEN WORKING IN AN IDLH CONFINED SPACE?

Q. WHAT KIND OF RULES EXISTS FOR SCBA USE IN HAZARDOUS WASTE/EMERGENCY RESPONSE?

Q. WHAT ABOUT FIRE BRIGADES?

Q. WHAT IMPACT DOES THE CURRENT VERSION OF 29 CFR 1910.134 HAVE ON OUR PRODUCTS?

• All tight fitting positive pressure respirators will require annual fit testing with the exact same make, model and size that is proposed for use.

Q. SO WHAT DOES THAT MEAN TO THE SCBA LINE?

Q. HOW SHOULD THE TEST BE DONE?

If you only have SCBA with the 7800S-AM Facepiece you will need a standard 7800S Facepiece. Use the Quantitative Fit test adapter and 2091 filter. Use any of the OSHA accepted fit test protocols.

Q. IF I HAVE A PERMIT REQUIRED CONFINED SPACE, ARE THERE STEPS I CAN FOLLOW TO CHOOSE THE RIGHT TYPE OF RESPIRATOR?

Open circuit SCBA - this filled with filtered compressed air rather than pure oxygen. (For underwater open-circuit breathing sets)

- Closed Circuit SCBA - For Longer duration supply of breathing apparatus, used in mines and tunnel rescue.

3. Self contained breathing apparatus details

SCBA Set contain high pressure cylinder with inhalation connection with back plate accessories.

Pressure Regulation

- 1st regulator gives reduced pressure range between 4 - 8 atmospheric pressure

- 2nd regulator is a demand valve which gives output pressure just above atmospheric pressure which gives air when a person breathing or continuous positive pressure.

There are two types of pressure system in face shield mask

- Negative pressure system: This found in older equipments and almost not used. When internal pressure of mask dropping below ambient pressure then it activate flow. In case of inaccurate face sealing it sucks outer air inside mask which has potentiality to cause accident.

- Positive suction system: This pressure inside face shield is slight high pressure then ambient outside pressure. Supply of air activated when pressure drop is created [Pressure drop is still above atmospheric pressure]. This system prevents outer gas inhalation.

SCBA Service time

SCBA Set cylinder decides its Capacity. It’s come with standard sizes 4 Liters, 6 Liters, 6.8 Liters.

It is also available in time duration on www.suresafety.com with 60 minutes, 45 minutes, 30 minutes and 15 minutes [ 15 minutes bottle is for only escape use]

SCBA Set service time can be calculated by following equation

Where Average human air consumption = 40 Liters / minutes

Safety escape time

|

10

|

Minutes

|

|

Volume (liters)

|

Pressure (Atmospheric)

|

SCBA Service Duration

|

|

4

|

200

|

26.67

|

|

4

|

300

|

40

|

|

6

|

200

|

40

|

|

6

|

300

|

60

|

There are 2 another factors which can reduce service time of breathing apparatus 25 – 50 %

1. Physical fitness and lung capacity of the person who is wearing it.

2. Type of work varies breathing speed of person.

When pressure drops below 55±5 atmospheric pressure it gives audio visual alarm on PASS system

1. Physical fitness and lung capacity of the person who is wearing it.

2. Type of work varies breathing speed of person.

When pressure drops below 55±5 atmospheric pressure it gives audio visual alarm on PASS system

4. USES of SCBA

Self- Contained Breathing Apparatus is used in

- Polluted environment with Chemical, Biologically, Radiology or Nuclear.

- Oxygen deficiency areas – Confined space, Toxic dusted area.

5. Self contained breathing apparatus specifications:

Breathing apparatus has some specification which monitored by Regulatory bodies following:–

- NFPA USA - National Fire Protection Agency

- NIOSH - National Institute for Occupational safety Health

- Europe 89/686/EEC

- European Standards EN 137: 2006

- ANSI - American National Standard Institute

- MSA – Measurement safety analysis

- WAC – Washington Administrative Code

General Specification

- SCBA must tested on temperature range -30°C to +60°C

- SCBA has 1200 liter filtered air

- SCBA shall be capable of providing minimum 30 minutes of service time

- SCBA has audio visual alarm which can be operated when pressure drops below 55±5 Atmospheric pressure. Audible alarm can be operated pneumatic air pressure or by electrically battery operated

- Maximum Cylinder service life is 20 years from manufacturing and advisable years are 15 years.

6. Cylinder carrying Practice

Cylinder is not handled with hand cover with Pressure Gauge or Air regulator. It sold be carried by neck of cylinder.

7. Check points of Apparatus

Daily Checkpoints

- Check that the cylinder pressure is sufficient or not

- Check physical condition of rubber gauge protector on air cylinder is properly positioned or not.

- Check Alarm system is working or not by closing main air regulator.

- Open the cylinder air regulator to check hose leakage or not.

- Check Alarm system is working or not by closing main air regulator.

- Check bypass valve working or not.

Weekly check

- Gauges are checked after use or weekly. Check Air cylinder pressure and remote pressure gauge reading is same or any deviation

- Physical condition of container

After use inspection

- Exhalation valve must cleaned properly after use

- Check speaking diaphragm & Ensure microphone is in center.

Cleaning and sanitizing procedure

- After each use of SCBA cleaning & sanitizing carried out.

- Remove electrical equipments outside like Voice amplifier, heads up display, Battery etc.

- Clean face shield accessories with wet water cloth. Don’t use alcohol or any cleaning solvent because it harms rubber

- Rinse mask through water [<120°C]

- Let accessories dry. Don’t use compressed air to dry.

Reference

SCBA Frequently Asked Questions

Q. WHEN SHOULD I USE SCBA?

A. An SCBA is the choice when dealing with any oxygen deficient atmosphere that is IDLH (Immediately Dangerous to Life or Health), or any environment that is unknown or has unknown levels of contaminants. This is possible because the wearer carries their own supply of breathable air.

Q. WHAT SIZE CYLINDER DO I NEED?

A. For a stand alone SCBA, you need a minimum of 30-minute rated life. This does not apply if the SCBA is equipped with an airline to operate in the positive pressure mode. Smaller time rated cylinders can then be used.

Q. WHAT KIND OF APPLICATIONS NEED SCBA?

A. The most common is called “Confined Space”. Others would be working with liquid spills or gas exposures that produce or could produce IDLH conditions.

EXAMPLES INCLUDE:

Confined Space

• Tank or reactor entry for maintenance or cleaning.

• Repair of gas lines or toxic chemical lines in trenches or pits.

• Working in sewers.

• Working in silos, storage tanks, pipelines.

• Working in truck or rail tank cars.

• Working in large machinery housings.

Working with liquids, gases, vapors and particulate

• HAZMAT response to toxic gas leaks such as chlorine and hydrogen sulfide.

• HAZMAT response to any unknown. This does not have to be in a confined space.

• First response emergency rescue of people overcome by atmospheric hazards.

• Escape from an area that has become IDLH due to accidental release of gases or vapors.

Q. WHAT IS A CONFINED SPACE?

A. Confined spaces are regulated under OSHA Confined Space Standard 29 CFR 1910.146. A confined space has very particular attributes. Notice none of these have anything to do with atmospheric hazards.

1. It is of a size and shape that will allow entry by a person.

2. There are few, perhaps only one, openings to entry or exit.

3. It is not designed for continuous occupancy.

Q. WHAT IS A PERMITTED CONFINED SPACE?

A. Now we get into area that might require respiratory protection. However, always remember this: Just because it is a permitted confined space does not mean SCBA or even any other form of respirator is required. Remember, permitted confined space has one or more of these attributes:

1. It contains or has the potential to contain a hazardous atmosphere;

2. It contains materials that potentially could engulf anyone in the space;

3. It has a design that potentially could trap or asphyxiate anyone in the space; and

4. It contains any other serious safety or acute health hazard.

The reason an SCBA is often needed for entry into a permitted confined space is because nothing has been done to characterize what is the potential or real atmospheric hazard. If you do not know, then an SCBA is required.

Q. WHAT IS A HAZARDOUS ATMOSPHERE IN A CONFINED SPACE?

A. An atmosphere that may expose employees to the risk of death, incapacitation, impairment of ability to self-rescue (that is, escape unaided from a permit space), injury, or acute illness from one or more of the following causes:

1. Flammable gas, vapor, or mist in excess of 10 percent of its lower flammable limit (LFL);

2. Airborne combustible dust at a concentration that meets or exceeds its LFL;

NOTE: This concentration may be approximated as a condition in which the dust obscures vision at a distance of 5 feet (1.52 M) or less.

3. Atmospheric oxygen below 19.5 percent or above 23.5 percent;

4. Atmospheric concentration of any substance for which a dose or a permissible exposure limit is published in 29 CFR 1910.146 Subpart G, Occupational Health and Environmental Control, or in Subpart Z, Toxic and Hazardous Substances, and which could result in employee exposure in excess of its dose or permissible exposure limit;

NOTE: An atmospheric concentration of any substance that is not capable of causing death, incapacitation, impairment of ability to self-rescue, injury, or acute illness due to its health effects is not covered by this provision.

5. Any other atmospheric condition that is immediately dangerous to life or health. NOTE: For air contaminants for which OSHA has not determined a dose or permissible exposure limit, other sources of information, such as Material Safety Data Sheets that comply with the Hazard Communication Standard 1910.1200, published information, and internal documents can provide guidance in establishing acceptable atmospheric conditions.

Q. WHAT KIND OF SCBA MIGHT BE NEEDED?

A. • An SCBA approved for entry and escape from a hazardous atmosphere. Minimum 30-minute rating.

• A combination ESCBA/SAR (Supplied air respirator) approved for entry and escape from a hazardous atmosphere. With combination ESCBA/SAR you must enter the contaminated area using the airline if the SCBA has a rated life of 3, 5, or 10 minutes. For 15-minute and higher ratings you can enter using the air cylinder as long as you use 20% or less of this air reaching the point where you plug into an airline. An alarm and gauge is required on the system.

Q. HOW DOES AN ATMOSPHERE BECOME OXYGEN DEFICIENT?

A. Generally this means less than 19.5% oxygen. OSHA exceptions to this are based on altitude and concentration. The condition could exist for several reasons:

• Combustion from fire, cutting torches, and welding arc;

• Inert gases like nitrogen displacing the oxygen;

• Rotting organic matter consumes oxygen; and

• Rusting of metals consumes oxygen.

Q. WHAT DOES OSHA REQUIRE WHEN WORKING IN AN IDLH CONFINED SPACE?

A. OSHA 1910.134 (g)(3) states:

• At least one employee located outside the IDLH atmosphere.

• Visual, voice, or signal line communication maintained between employee(s) inside the IDLH atmosphere and outside the IDLH atmosphere.

• Employee(s) located outside the IDLH atmosphere trained and equipped to provide effective emergency response.

• Employer or designee notified before employee(s) located outside the IDLH atmosphere enter to emergency rescue.

• Employer or designee to provide necessary assistance.

• Employees located outside the IDLH atmosphere equipped with: Appropriate retrieval equipment or equivalent means for rescue. Pressure demand SCBA

.

Q. I HAVE HEARD OF BUDDY BREATHING. WHAT ACTUALLY IS THIS?

A. • More than one person sharing the air from one SCBA, usually in an escape.

• Use in this way voids NIOSH approval.

• OSHA allows it only if it does not reduce the airflow to the primary user. 3M does not recommend this activity and our new SCBAs do not have this capability.

Q. WHAT KIND OF RULES EXISTS FOR SCBA USE IN HAZARDOUS WASTE/EMERGENCY RESPONSE?

A. 29 CFR 1910.120 provides:

• (g)(3)(iii) Positive pressure SCBA or combination SAR/SCBA required if there is substantial possibility that chemical exposures may be IDLH or impair ability to escape.

• (q)(3)(x) Switching SCBA cylinders among manufacturers is acceptable.

• Appendix B Levels A, B, C, D protective equipment ensembles described. Levels A & B include positive pressure SCBA or Type C/SCBA.

Q. WHAT ABOUT PRESSURE TESTING THE SCBA CYLINDERS?

A. This is required and is done with water under high pressure, hence the name hydrostatic testing. The length of time between tests depends on the material of the cylinder. The date of the test is on the cylinder. Steel - Hydrostatic test interval: 5 years Aluminum - Hydrostatic test interval: 5 years Composite - Hydrostatic test interval: 3 years. Service life limited to 15 years

Q. WHAT ABOUT FIRE BRIGADES?

A. OSHA 1910.156 (f) requires the following:

• SCBA required for fire brigades working inside buildings or confined spaces where toxic combustion products or O2 deficiency may be present.

• "Buddy-breathing" devices are acceptable.

• Switching SCBA cylinders among manufacturers is acceptable.

• SCBA must be at least 30-minute duration.

• SCBA must have an audible low air warning.

• Only pressure demand SCBA for fire fighting.

Q. WHAT IMPACT DOES THE CURRENT VERSION OF 29 CFR 1910.134 HAVE ON OUR PRODUCTS?

A. The requirements for fit testing have changed. In the past, tight fitting positive pressure respirators did not have to be fit tested. NOW THEY DO HAVE TO BE FIT TESTED.

• All tight fitting positive pressure respirators will require annual fit testing with the exact same make, model and size that is proposed for use.

• Fit factors of 100 or greater are required for half facepiece, 500 or better for full facepiece.

• Testing can be either Quantitative or Qualitative and is done in the negative pressure mode. This is true even if the actual use will be in the positive pressure mode.

Q. SO WHAT DOES THAT MEAN TO THE SCBA LINE?

A. Customers who have need for SCBA are reluctant to have products in their plant that has different full facepieces. This would mean having to double up on fit testing. It seems obvious to the customer that all types of respiratory protection in the plant using full facepieces should use the same one. 3M bases its 7800S and SCBA on the same Full Facepiece seal. A 7800S can be used to face fit both negative pressure and SCBA users.

Q. HOW SHOULD THE TEST BE DONE?

A. If both the 7800S and 7800-AM facepieces are in use at a plant simply fit test the 7800S using appropriate P100 filters and any of the OSHA accepted fit test protocols. Since the 7800-AM facepiece is exactly the same make, model and size, testing the 7800S covers both.

If you only have SCBA with the 7800S-AM Facepiece you will need a standard 7800S Facepiece. Use the Quantitative Fit test adapter and 2091 filter. Use any of the OSHA accepted fit test protocols.

Q. IF I HAVE A PERMIT REQUIRED CONFINED SPACE, ARE THERE STEPS I CAN FOLLOW TO CHOOSE THE RIGHT TYPE OF RESPIRATOR?

A. Yes. The following chart is the map. It talks about hazardous atmospheres that were defined earlier and also Respiratory Hazards. Respiratory Hazards are simply an airborne concentration of a gas, vapor, particulate or combination that may or may not have acute effects

No comments: